Infrastructure

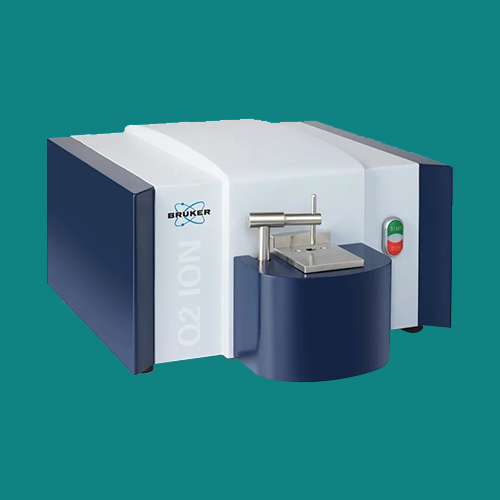

Selection the right raw material and processing them correctly forms a Fundamental step towards ensuring quality excellence. Deploys a robust identification and traceability mechanism to avoid mix up and unintended use of the raw material.

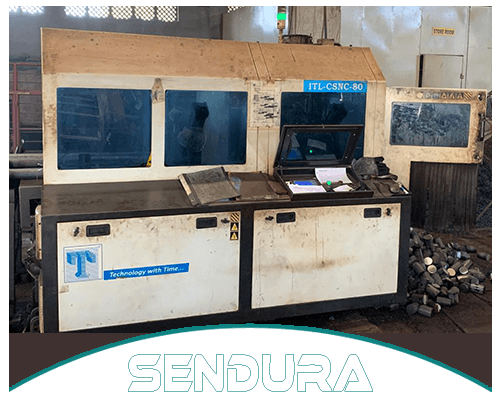

Cutting Shop

Equipped with the circular saw cutting machine with auto loader and band saws with capacity up to 200 mm.

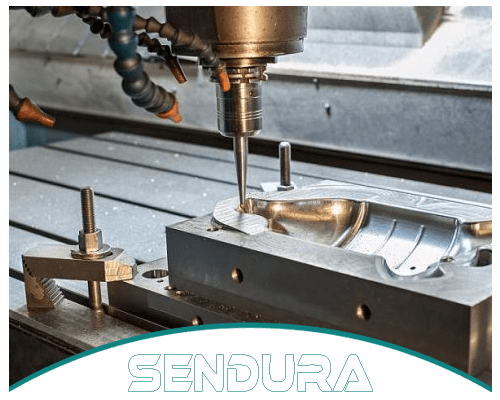

Die Shop

A completely equipped Tool Room with supported by CAD/CAM Technology, Die sinking machines facilities for ensuring perfect repeatability with a highly experienced design team.

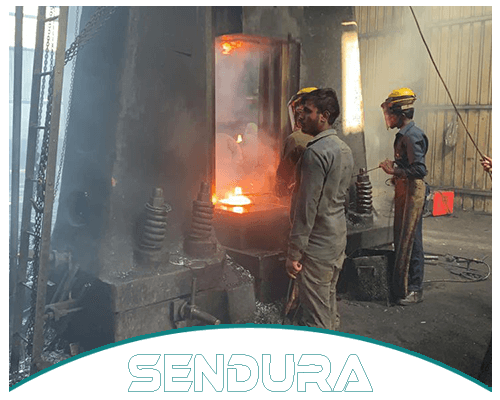

Forge Shop

- Three Hammers with capacity of 1.0, 1.25. 2.0 and 3.0 ton enabling single piece forging of weight up to 30 Kg’s.

- Yearly production capacity of 12000 Tons.

- Induction Heater having accept / reject mechanism. High and Low temperature both are available which are calibrated regular intervals.

- Hydraulic Coining Press in which pressure is applied on the surface of the forging in order to obtain closer tolerances, smoother surfaces.

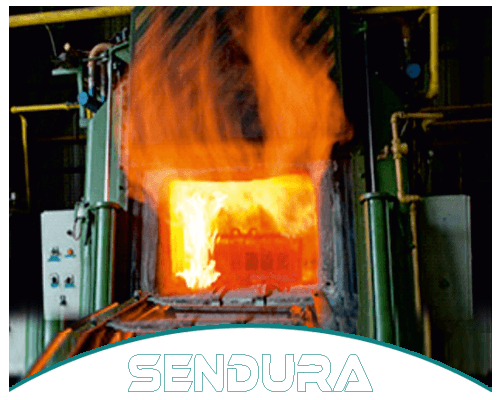

Heat Treatment

We have tie-up with heat treaters for various heat treatment processes like Normalizing, Quenching & Tempering, ISO Thermal Annealing & Solution Annealing etc.

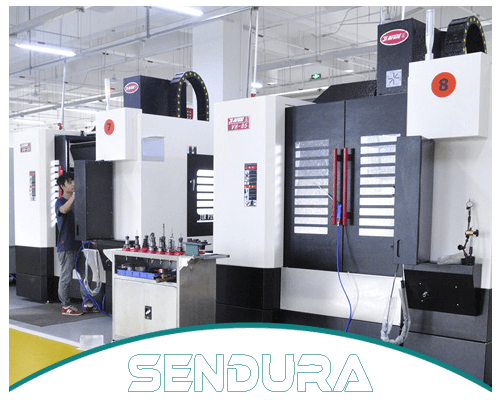

Machine Shop

We have able to supplies components with Proof machining to Finish Components and has tie up with approved machining suppliers with facilities like various conventional CNC & VMC machines.

| LIST OF MACHINERY & EQUIPMENT | |||||

|---|---|---|---|---|---|

| Sr. No. | Machine / Equipment Description | Code No. | Make / Model | Capacity / Specification | Location |

| 1 | Belt Drop Hammer | SF/BDH/01 | NKH | 1.25 ton | Forge Shop |

| 2 | Belt Drop Hammer | SF/BDH/02 | Rajan | 1.00 ton | Forge Shop |

| 3 | Belt Drop Hammer | SF/BDH/03 | Ratan | 3 ton | Forge Shop |

| 4 | Belt Drop Hammer | SF/BDH/04 | NKH | 2 ton | Forge Shop |

| 5 | Induction Billet Heating Furnace | SF/IBH/01 | Plasma | 350 Kw | Forge Shop |

| 6 | Induction Billet Heating Furnace | SF/IBH/02 | Inductotherm | 300 Kw | Forge Shop |

| 7 | Induction Billet Heating Furnace | SF/IBH/03 | Inductotherm | 600 Kw | Forge Shop |

| 8 | Induction Billet Heating Furnace | SF/IBH/04 | RA | 400 Kw | Forge Shop |

| 9 | Trimming Press | SF/TP/01 | NKH | 150 Ton | Forge Shop |

| 10 | Trimming Press | SF/TP/02 | Rajan | 150 Ton | Forge Shop |

| 11 | Trimming Press | SF/TP/03 | Ratan | 400 Ton | Forge Shop |

| 12 | Coining Press | SF/CP/01 | Hari Eng. | 125 Ton | Forge Shop |

| 13 | Air Compressor | SF/AC/01 | Ingersoll rand | 15 HP | Forge Shop |

| 14 | Air Compressor | SF/AC/02 | Ingersoll rand | 10 HP | Forge Shop |

| 15 | Air Compressor | SF/AC/03 | Ingersoll rand | 15 HP | Forge Shop |

| 16 | Air Compressor | SF/AC/04 | Ingersoll rand | 10 HP | Forge Shop |

| 17 | Screw Air Compressor | SF/AC/05 | ELGI | 15 HP | Cutting Shop |

| 18 | Band saw M/c | SF/BC/01 | Krishna | Ø200 mm | Cutting Shop |

| 19 | Band saw M/c | SF/BC/02 | Krishna | Ø200 mm | Cutting Shop |

| 20 | Band saw M/c | SF/BC/03 | Krishna | Ø200 mm | Cutting Shop |

| 21 | Band saw M/c | SF/BC/04 | Universal | Ø200 mm | Cutting Shop |

| 22 | Band saw M/c | SF/BC/05 | Universal | Ø200 mm | Cutting Shop |

| 23 | Band saw M/c | SF/BC/06 | Universal | Ø200 mm | Cutting Shop |

| 24 | Band saw M/c | SF/BC/07 | Universal | Ø200 mm | Cutting Shop |

| 25 | Milling M/c | SF/MM/01 | Bhamber / VM 5B | XYZ Axis 18 | Die Shop |

| 26 | Milling M/c | SF/MM/02 | Bhamber / VM 5B | XYZ Axis 18 | Die Shop |

| 27 | Radial Drill M/c | SF/RD/01 | Siddhapura | 40 mm | Die Shop |

| 28 | Lath M/c | SF/LT/01 | BK | 10 ft. | Die Shop |

| 29 | Lath M/c | SF/LT/02 | Bharat | 7 ft. | Die Shop |

| 30 | Lath M/c | SF/LT/03 | BK | 4 ft. | Die Shop |

| 31 | Lath M/c | SF/LT/04 | BK | 4 ft. | Die Shop |

| 32 | Shaping M/c | SF/SP/01 | Gemini | 19″ | Die Shop |

| 33 | CSNC M/c | SF/CSNC/01 | ITL | Ø80 | Cutting Shop |

| 34 | CSNC M/c | SF/CSNC/02 | ITL | Ø100 | Cutting Shop |

| 35 | Tool & Cutter Grinder | SF/TG/01 | Rajlaxmi | 0.5 HP / 6″ x 3/4″ | Die Shop |

| 36 | Tool & Cutter Grinder | SF/TG/02 | Rajlaxmi | 0.5 HP / 6″ x 3/4″ | Die Shop |

| 37 | Welding M/c | SF/WL/03 | Ador | Thyroluxe 600 | Die Shop |

| 38 | Bench Grinder | SF/BG/01 | Rajlaxmi | 2 HP / 12″ x 1.5″ | Grinding Shop |

| 39 | Bench Grinder | SF/BG/02 | Rajlaxmi | 2 HP / 12″ x 1.5″ | Grinding Shop |

| 40 | Water Cooling Tower | SF/CT/01 | Raj | 150 TR Cross Flow | Out side of Die Shop |

| 41 | Water Cooling Tower | SF/CT/02 | Raj | 150 TR Round | Out side of Die Shop |

| 42 | Letter Punching Fly Press | SF/LP/01 | New Karchi | 6K | Final Inspection |