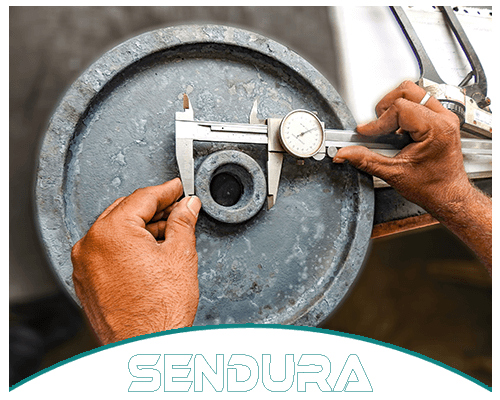

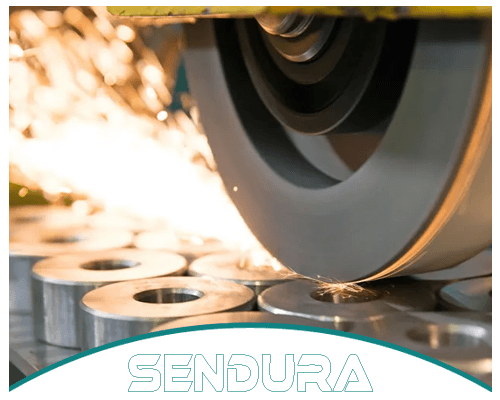

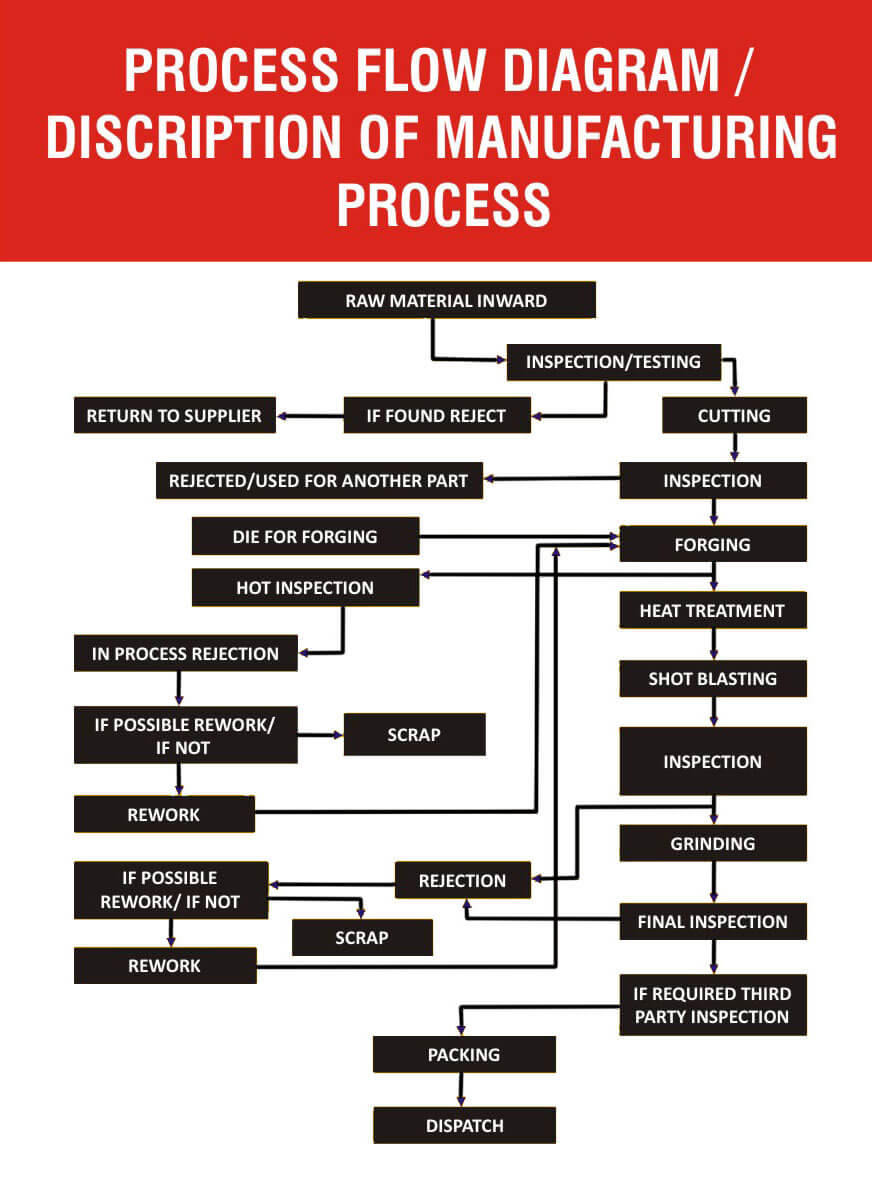

We at Sendura Forge Pvt. Ltd. employ the best forging manufacturing processes to get quality products with excellent durability and work-life. Our labs are equipped with the latest technologies and our workforce is skilled in these technologies to design and manufacture the best industrial components through the latest manufacturing processes. Our forging process is an ideal option for applications that require performance and safety for speed and energy efficiency.